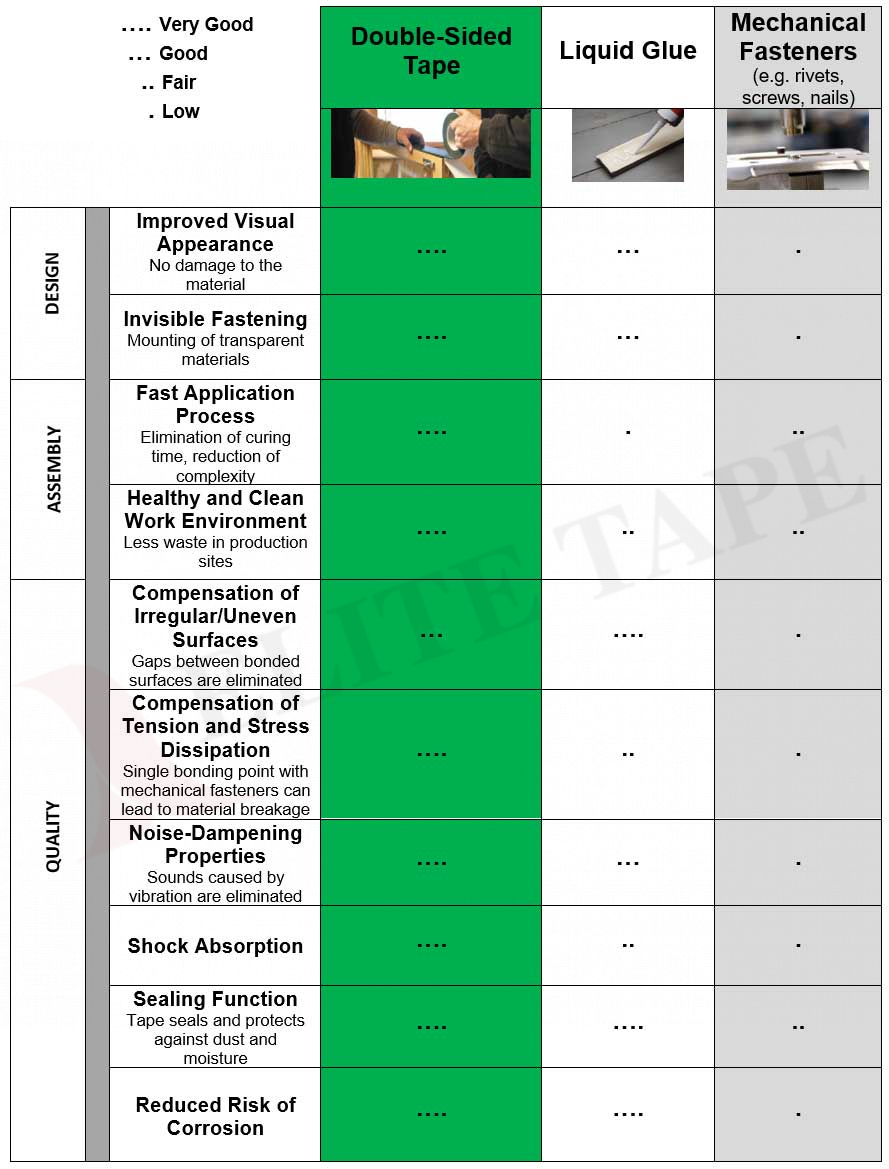

Manufacturers in a variety of industries know the significant benefits of working with tapes versus liquid glue, sealants and other mechanical fasteners. Tapes offer a permanent bond, no cure time, no fumes and no messy clean ups, which is preferred for bonding in roofing, appliances, semiconductors, space vehicles, building & construction and many other industries.

Design Benefits

- Visually Appealing

- Replaces Screws & Mechanical Fasteners

- Allows Flexibility in design by bonding substrates of all shapes & sizes

- No Messy Clean ups and No Surface Damage

- No chemical bond or cure time is needed with tape.

Ease of Assembly

- No training required when using tape

- Hand or Dispenser Applied

- Significant cost savings can be found when using tapes,

- No odors or fumes

- No brushes, application tools, mixing or cure time required

- Fast application and permanent bond

- Tape has no waste or clean up

Quality

- Tapes are ideal for gap-filling on irregular or uneven surfaces.

- Tapes offer tension and stress dissipation, noise dampening and shock absorption

- Tape seals to protect against dirt and moisture and reduces risk of corrosion.

- Tapes are formulated to bond to a wide variety of substrates

- Tape can be used for many applications in the manufacturing area

Versatility

- Tapes can offer – UV resistance, Temperature extremes, Waterproof, Humidity resistance, Chemical resistance, Permanent or Removable Bond.

- Tapes are available in a variety of sizes, colors, widths. There are double-sided, single-sided, metal detectable, tissues, fabrics, films and foils.

Due to its design, ease of use, quality and versatility, customers widely consider adhesive tape to be the industry standard for fastening. The best way to understand how a tape can improve your process is to speak with a knowledgeable tape converter.

Elite Tape can offer a customized specialty tape for your specific application. We also offer die-cutting and custom printing with your company logo. Elite Tape is a converting partner who can provide tape knowledge, expertise and free samples which limits both your risk and your costs and can guarantee you get the best performance from your products and your manufacturing process.

855-770-TAPE (8273)

855-770-TAPE (8273) CONTACT US

CONTACT US